Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

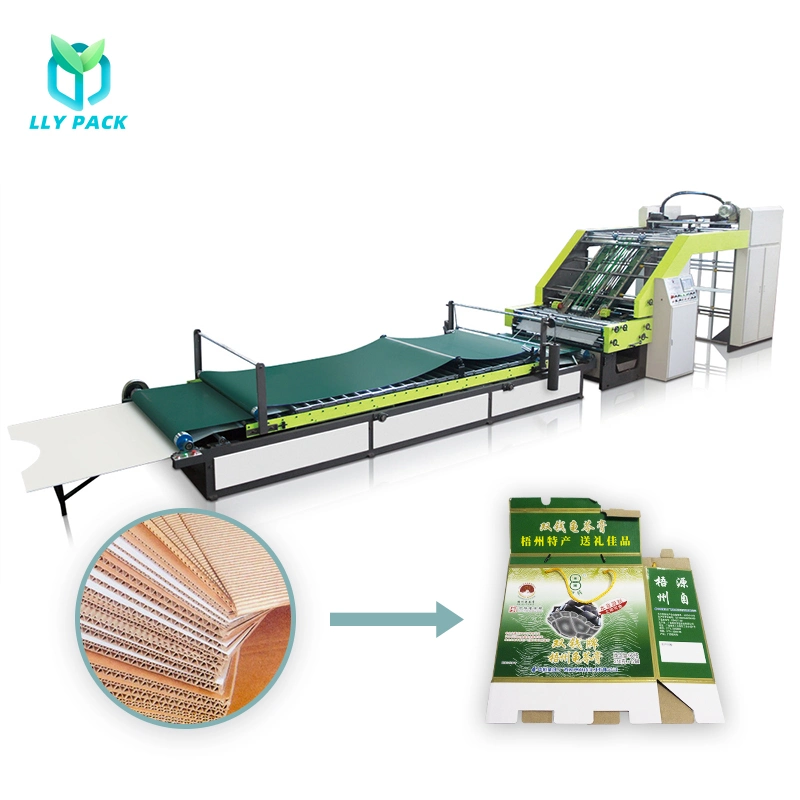

Brand: LLY PACK

Types Of: Laminating Machine

Applicable Industry: Manufacturing Plant, Manufacturing Plant

Out-of-warranty Service: Online Support, Video Technical Support

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Not Available

Mechanical Test Report: Not Available

Marketing Type: Ordinary Product, Ordinary Product

Core Component Warranty Period: 1 Year

Status: New

Degree Of Automation: Automatic

Place Of Origin: China

Warranty Period: 1.5 Years

Membrane Material: Paper

Weight: 8500 Kg

Max Paper Size: 1700x1650mm

Min Paper Size: 360x380mm

Top Sheet Thickness: 128g/M2-450 G/M

Bottom Sheet Thickness: 0.5mm-10mm Sheet To Sheet Lamination:250+Gsm

Max. Working Speed: 148m/Min

Max. Machine Speed: Lamination Part 14800 Pcs/Hr Stacker 12000 Pcs/Hr

Transportation: Ocean,Land,Air,Express

Supply Ability: 400 Piece/Pieces Per Year

Port: Foshan

Payment Type: L/C,T/T

| MODEL | HBF-170 |

| Max paper size | 1700x1650mm |

| Min paper size | 360x380mm |

| Top sheet thickness | 128g/m2-450 g/m2 |

| Bottom sheet thickness | 0.5mm-10mm Sheet to sheet lamination:250+gsm |

| Max. working speed | 148m/min |

| Max. machine speed | Lamination part 14800 pcs/hr Stacker 12000 pcs/hr |

| Lamination error | ±0.5mm to ±1.5 mm |

| Machine power | 23.57kw+9kw |

| Actual power | 15kw |

| Machine size(L×W×H) | 22940×2300×2600mm |

| Machine weight | 8500kg+5800kg |

1. Q: Are you a manufacturer, trading company or a third party?

A: We are a manufacturer, located in National High-tech Industrial Zone, Sanshui, Foshan City, Guangdong Province, China. Warmly welcome to visit our company.

2. Q: What is your minimum order quantity, can you send me samples?

A: Our minimum quantity is 1 set.

With over 3500+ sucessful installation experience in the last 22 years, we provide tailor-made solutions as per customer's demand.

3. Q: How does your factory do regarding quality controlling?

1). 22 Years of Specialization in Corrugated Industry Solutions that delight

2). Over 3500+ successful installation Corrugated Cardboard Production Line

3). Quick Responsive Professional Pre-sales Service

4). Top machinery R&D team

5). A state-of-the art factory with full set up of manufacturing facilities, including 4 Sets of advanced 5-face High Precision

CNC Center

6). Strict inspection before delivery

7). All-round after-sales Service System

8). Fuli is the unique company who drafts the latest version of national industry standard for corrugated machines in China

4. Q: How about the after-sale service?

All-round after-sales Service System

Engineers team provides solutions in the field of Mechanic/ Electric/ Operation.

TM online for 24 hours.

Online Quick Responsive service: Email, skype, MSN, FB, Linkin, Wts, IG.

One year warranty period under normal use for machines.

Product Categories : Carton Machine > Laminating Machine

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.